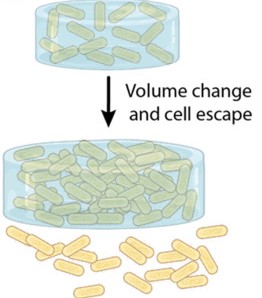

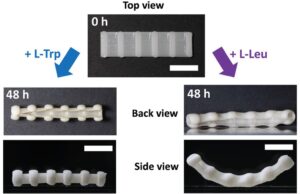

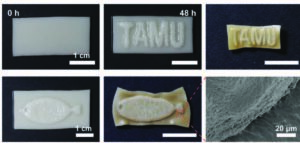

Engineered Living Materials are composites of non-living and living composites. We often make synthetic hydrogels with embedded bacteria or yeast. We are studying the fundamental properties of these materials and applying them to solve important engineering problems. Some of our latest work includes creating materials that grow into a predetermined size and shape. This growth can even be powered by food waste. We are also creating materials that can controllably delivery probiotics, including yeast and bacteria.

Key Citations:

Advanced Functional Materials, 2021, p. 2106843, doi:10.1002/adfm.202106843

Biomaterials Advances, 2022, p. 213182, doi:10.1016/j.bioadv.2022.213182

ACS Applied Materials & Interfaces, vol. 14, no. 17, 2022, pp. 20062–72, doi:10.1021/acsami.2c03109

Science Advances, 6(3): eaax8582, doi/10.1126/sciadv.aax8582